Radial Eductor®

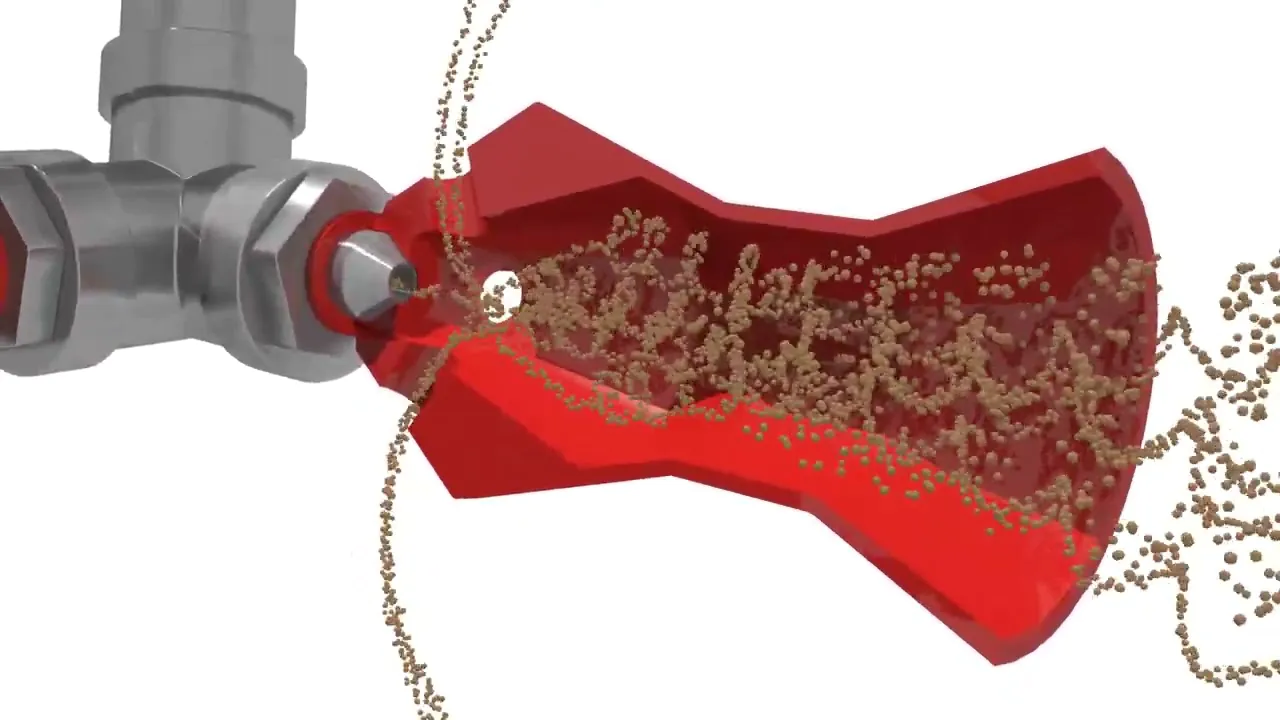

Vortex Radial Eductors achieve highly effective fluid mixing and agitation, preventing solid settling in applications such as drilling mud pits, hydration and chemical reaction enhancement. They use pressurized fluid energy to reliably maintain, mix and pump during tank mixing.

Vortex Ventures offers three distinct models of tank mixing eductors, providing a range of use cases depending on your mixing needs. All models excel at eliminating tank sludge and reducing cleaning time, all while avoiding the typical maintenance required for mechanical agitators.

Whether used as a primary means of drilling mud pit agitation or to complement existing agitators, Vortex Radial Eductors reliably enhance fluid movement to eliminate dead zones in tank mixing.

Enhanced Fluid Movement

No Moving Parts

Zero required maintenance

Low-cost alternative to mechanical agitators

Fully homogenous

fluid mix

Reduces Cleaning Time

Simple, Robust Design

Eliminates tank sludge

Perfect for demanding mixing jobs

Bring Tank Dead Zones to Life

Streamline your fluid mixing with Vortex Radial Eductors that take the hassle out of tank agitation. See these tank eductors in action below as they increase fluid movement and eliminate tank sludge.

Products

Discover More Vortex Products

Explore a range of best-in-class Vortex Ventures products that turn your solvents into solutions.

-

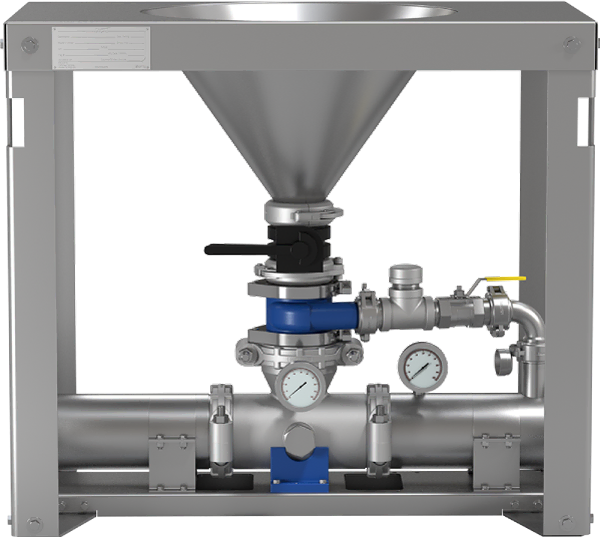

Learn More about Lobestar® Shear-Mixers

Learn More about Lobestar® Shear-MixersLobestar® Shear-Mixers

Venturi-based mixers that deliver fast, homogeneous slurries — from drilling mud and construction materials to sucrose, citric acid, and other industrial powders — all with no moving parts.

-

Learn More about Vortex MixMate®

Learn More about Vortex MixMate®Vortex MixMate®

Safe, controlled mixing of hazardous chemicals such as caustic soda for oilfield operations—improves HSE and consistency.

-

Learn More about Dust Recovery System (DRS)

Learn More about Dust Recovery System (DRS)Dust Recovery System (DRS)

Captures dust during powder transfer — reducing additive loss and improving safety in applications from drilling mud and construction materials to sucrose, citric acid, and other industrial powders.

Frequently Asked Questions

Browse answers to common questions about the Radial Eductor and processes.

What is the required head and flow rate to operate a Radial Eductor?

All Radial Eductor models require somewhere between 92 -185 feet of head (40 – 80 PSI with fresh water) for optimum performance, and effective operation can often be achieved with 75 feet of head.

- Model RE2000 needs about 135 – 192 GPM (30.6 m3/hr – 43.6 m3/hr) of flow.

- Model RE1500 needs about 69 – 100 GPM (15.6 m3/hr - 22.7 m3/hr) of flow.

- Model RE1000 needs about 45 – 65 GPM (10.2 m3/hr – 14.7 m3/hr.) of flow.

What is the pressure limit of the Radial Eductor®?

Radial Eductors are High-volume, Low-pressure system components and they are rated to a maximum pressure of 150 PSI and typically require higher volumes of motive flow for operation.

How resistant to wear are Radial Eductors?

Radial Eductors are constructed of a specific composition of molded polyurethane that is highly resistant to abrasion by solids and erosion by many different chemicals. In applications with highly abrasive, solids laden fluids, such as drilling mud, the urethane composition used in the Radial Eductor wears at a rate of 7 to 8 times slower than steel.

What is the temperature limit of the Radial Eductor?

The operating temperature limit is -20°F (-28.8°C) to 150°F (65°C.) The standard urethane construction material has a maximum temperature limit of 160°F (71°C,) but the eductors should not be operated above the operating temperature for extended periods of time because the urethane will soften and deform.

Are Radial Eductors offered in other materials of construction besides urethane?

The standard version of the Radial Eductor is molded out of urethane. Standard Radial Eductors constructed in other materials besides urethane are not offered. Consideration may be given to offering eductors in alternative materials if the volume of units needed justify engineering and production efforts.

What type of pump should be used to supply motive flow to the Radial Eductor(s)?

The flow and pressure required to operate Radial Eductors should be delivered by centrifugal pumps, but positive displacement or other types of pumps that provide steady, constant flow can be used as well.

Where is the source of the motive flow?

The motive fluid pumped through the Radial Eductors may be drawn out of the vessel and recirculated back into the same vessel through the eductors; or it may come from a secondary source, such as another vessel or reservoir.

Can Radial Eductors be used with mechanical, paddle agitators?

Yes. They can be used in conjunction with mechanical agitators to prevent settling of solids in the corners of rectangular tanks, or they can be used without mechanical agitators as the primary means of agitation.

Does Alfa Laval supply the manifold piping along with the Radial Eductors?

No. Vortex Ventures does not supply the manifold piping for mounting the Radial Eductors and energizing them with motive flow. However, Vortex Ventures can review the application parameters and recommend the optimal configuration for the manifold and the positioning of the eductors.

What is the total discharge flow of a Radial Eductor system and how is it different from the turnover rate of mechanical agitators?

The total discharge flow is the total rate of inlet plus induced fluid flow that will pass through all the eductors inside a vessel. This is a quantifiable measure that only partially indicates how efficient the tank mixing eductor system is, but it only takes into consideration the fluid passing through the eductors and does not account for the additional fluid entrainment and displacement of the discharge plumes. The turnover rate of a mechanical agitator is determined by the displacement of the agitator blades as they rotate in the vessel.

What differentiates the Radial Eductor’s performance from that of competitive tank mixing eductors despite similar turnover ratios?

The turnover ratio of any tank mixing eductor is commercially expressed as a ratio of inlet, motive flow to the volume of fluid induced by the motive jet and only accounts for the fluid that passes through the eductor. This value only partially indicates the total effectiveness of the eductor and the “true” turnover rate of the entire fluid volume of a vessel encompasses this value, as well as the total fluid movement created by the eductor plumes. Given the complexities of fluid dynamics and multiple variables that change from application to application, this “true” turnover rate is very difficult to quantify. The “true” turnover rate is essential for effective tank agitation, and it is maximized by the strong rotational energy of the Radial Eductor plume, which entrains and displaces a greater volume of fluid than paddle agitators and other tank eductors.

Reach Out

Contact a Vortex Ventures export to place orders and find the best fit for your mixing needs.